Throughout industries from life sciences to electronics, ultra-high decision and precision elements are sometimes required for innovation – particularly when that innovation is pushed by miniaturization. As merchandise and know-how get smaller, so do the intricacies of the elements which might be the sum of the entire. Many engineers and product designers are turning to 3D printing to fabricate these extremely exact, small-scale elements. Additive manufacturing is recently proving to be an environment friendly choice when in comparison with conventional molding.

Micro-3D printing is used to create high-precision tiny elements for medical units, optics, photonics, microfluidics, and client packaged items. Many of those elements have turn into the spine of customized healthcare units. They’re additionally utilized extensively in aerospace and automotive.

To get a deeper look into developments in micro-3D printing, we checked in with John Kawola, CEO of International Operations at Boston Micro Fabrication (BMF).

What are the benefits of micro-scale 3D printing in producing elements?

John Kawola: For a few years, creating molds for prototyping was the one resolution for micro elements, however that methodology was time-consuming and expensive. At this time, many industries and purposes use additive manufacturing as a cheap choice for on-demand prototyping and manufacturing, but it surely additionally permits engineers to push the boundaries of innovation.

At BMF, our clients are sometimes on the lookout for a stage of precision that’s merely inconceivable to realize with conventional manufacturing strategies like machining or molding. BMF’s Projection Micro Stereolithography (PµSL) know-how permits clients to persistently obtain extraordinarily small options with high-precision, decision, and accuracy.

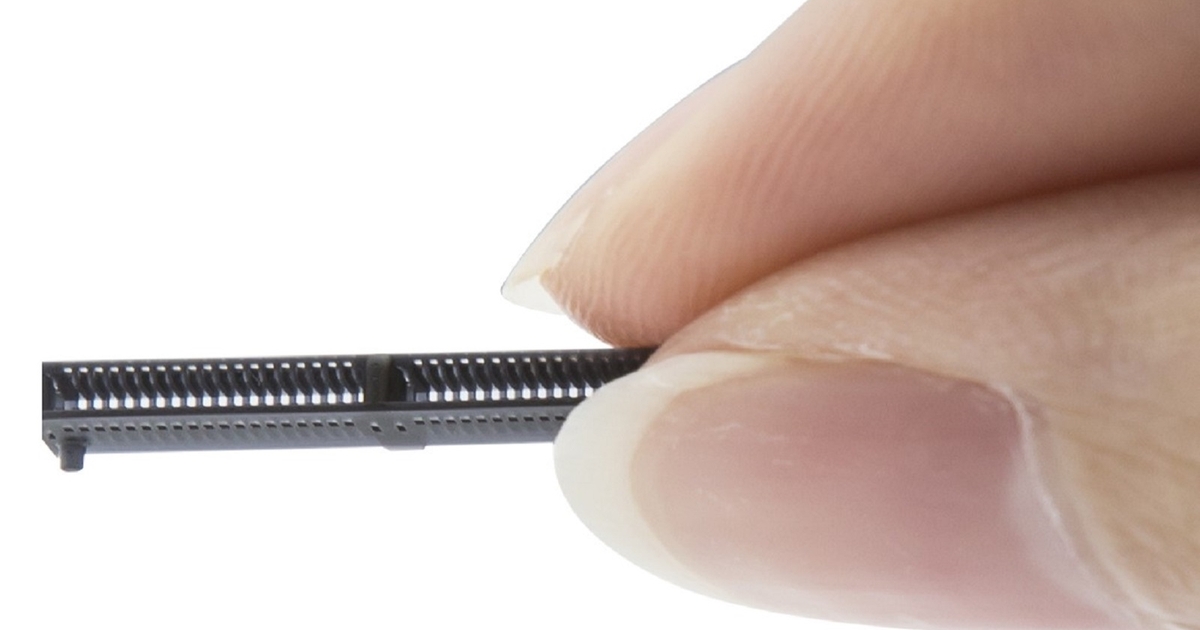

Picture courtesy of Boston Micro Fabrication.

We’ve additionally began to develop end-applications the place we really feel our know-how is uniquely suited to addressing trade ache factors. For instance, UltraThineer veneers – the world’s thinnest beauty dental veneers – wouldn’t be attainable to create with out micro-scale 3D printing.

Clarify the necessity for bigger elements with the precision and high quality related to micro-scale manufacturing.

John Kawola: Excessive precision isn’t simply vital for micro-sized elements. As product design continues to be a driver of innovation, the demand for extremely exact and correct elements stays, no matter half measurement. Whereas BMF is usually related to micro prints, that are on the core of our enterprise, we are able to additionally print bigger elements with a construct space of 100 x 100 x 75mm. We constructed our microArch S350 platform particularly to handle a market want for individuals who want excessive accuracy and precision, however not on the very excessive decision of our different programs. It’s a 25µm platform that may print at sooner speeds utilizing engineering-grade supplies to allow producers who might not want tremendous excessive decision, however to whom accuracy and precision are vital.

How has BMF redefined the standard limits of measurement in additive manufacturing? And why was this vital?

John Kawola: Previous to BMF, there have been no choices accessible to prototype micro sized elements with complicated geometries and small options outdoors of conventional manufacturing strategies, corresponding to micro injection molding. What many firms discover is that the smaller the half, the tougher and expensive it’s to fabricate utilizing conventional strategies. Our PμSL know-how leverages gentle, customizable optics, a high-quality motion platform and managed processing know-how to supply the trade’s most correct and exact high-resolution 3D prints for product improvement, analysis and industrial quick run manufacturing.

Picture courtesy of Boston Micro Fabrication.

At BMF, we offer superior manufacturing options for ultra-high precision purposes as a result of we noticed a market want for micro-precision elements with dimensional accuracy and precision throughout industries and within the completely different phases of product improvement from prototyping to manufacturing.

What was required to develop automation and speeds wanted for short-run manufacturing of ultra-high-resolution elements?

John Kawola: The power to get excessive decision, accuracy and precision with 3D printing depends on a number of elements. These embody the decision of the optics, the precision of the mechanical programs within the machine, the management of the publicity and the resultant curing, the interplay between the half and required help buildings, and, lastly, the general measurement of the half and the flexibility to manage tolerances throughout the construct.

Every of our printers has options that contribute to a step-and-repeat course of that enables for elements with excessive decision and managed processing know-how to supply extremely exact objects. The complete microArch assortment additionally features a customizable high-resolution optical system and motion platform, real-time picture monitoring, auto focus and publicity compensation, and operation software program with a streamlined interface and buyer parameter settings. The microArch 3D printing system is ready to notice ultra-high decision, large-area printing that’s utilized in industrial prototyping and short-run manufacturing.

Clarify the refinements in {hardware}, software program, and materials science wanted to perform this.

John Kawola: BMF’s 3D printers use PµSL know-how, which is a type of stereolithography (SLA) that includes a DLP® gentle engine, precision optics, movement management, and superior software program. SLA produces elements in layers utilizing a photochemical course of. A photosensitive liquid resin is uncovered to gentle in order that polymeric cross-linking and solidification happens. With PµSL know-how, a flash of ultraviolet (UV) gentle causes the speedy photopolymerization of a complete layer of resin.

.png?width=700&auto=webp&quality=80&disable=upscale)

Picture courtesy of Boston Micro Fabrication.

The PµSL course of we use is high down. The highest-down scheme not solely minimizes the variety of help buildings required, but in addition offers a option to cut back the injury to small options and take away bubbles utilizing a scraper that runs throughout a clear membrane. No helps are wanted to safe the underside floor to the print floor and restricted helps are required for overhangs because of the interplay of usually gentle weight elements and buoyancy of the resin. PµSL programs from BMF can obtain XY decision all the way down to 2 µm, minimal characteristic measurement of 10 µm and dimensional tolerance as tight as +/- 10 µm, the know-how helps steady publicity for sooner processing.

.jpeg?width=194&auto=webp&quality=80&disable=upscale)

Picture courtesy of Boston Micro Fabrication.

John Kawola is CEO for International Operations of Boston Micro Fabrication (BMF). He has greater than twenty years of enterprise management expertise throughout the additive manufacturing, 3D printing and supplies science industries. BMF is targeted on introducing and scaling micro-3D printing know-how to a spread of industries that demand a excessive stage of decision and precision.