Over the past a number of a long time, the design of robots has moved from an instructional train and the area of deep-pocketed firms to the world of start-ups, hobbyists, and on a regular basis individuals. Personalized and modular platforms like LEGO Mindstorm, Maker, quite a few Arduino-based platforms, and lots of extra can be found to newbies. Conversely, skilled engineers can use any variety of CAD-based design and simulation methods to assist in creating extra complicated industrial robots.

Whatever the ease or issue in designing a robotic, two issues stay fixed: the talents wanted and the fundamental lifecycle growth course of. The next article will cowl every matter briefly and its relevance as we speak.

Robotic Design From Then to Now

The design of robots has come a great distance since their begin within the Nineteen Sixties when their primary utility was on the manufacturing unit ground. Over the last decade, manufacturing unit robots—referred to as collaborative robots or cobots—have superior to work side-by-side with people, sometimes in manufacturing environments. Growing collaborative robots requires creating many complicated methods to sense, talk, and transfer alongside people safely and successfully.

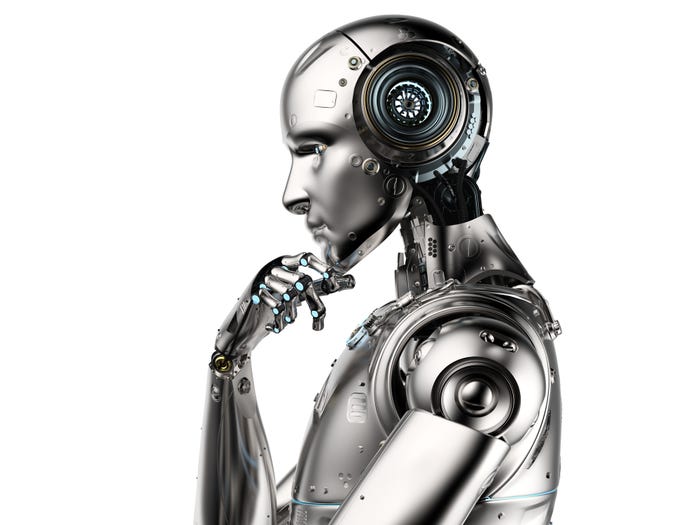

Within the very close to future, robots will likely be designed and taught to do duties with the addition of synthetic intelligence (AI) applied sciences. Incorporating AI into robotics considerably will increase automation capabilities in manufacturing, innovation, and price effectiveness. The addition of this expertise is sort of a change from previous automation enhancements, which allowed robots to interchange mundane, well-understood, and really repetitive duties.

Robots have moved past the manufacturing ground to virtually each different trade. However one of many vital robotic developments that transcended all markets is mobility, which mixes applied sciences from all key sectors like sensors, actuators, embedded imaginative and prescient, AI markets, edge computing, and extra. Implementation of robotic mobility is rising on the manufacturing ground, in hospitals, and residential care throughout the bottom, air, and water.

Immediately’s cell robots thrive in a large number of environments and purposes. Fleets of cell robots with laptop vision-based navigation now ship meals orders throughout main universities. Cell robots in manufacturing environments have gotten a extra frequent selection for duties akin to supplies transport and machine loading and unloading. Underwater robots are going locations the place few people may survive, just like the ocean’s depths, to drones flying into large forest fires to gather very important knowledge. Cell robots are even strolling on the ceiling of properties to deliver wanted providers whereas avoiding furnishings and ground litter.

Rendering of robots delivering meals in eating places. Oselote/iStock/Getty Photos Plus through Getty Photos

Outdoors of the manufacturing unit and warehouse flooring, human-friendly cobots are discovering acceptance within the medical and hospital halls. Along with their gentleness, these cell robots cannot be contaminated by viruses like COVID-19. Robotic methods, akin to illness prevention, analysis and screening, and affected person care, have been important in medical care.

Regardless of the utility, from life-saving providers to distinctive toys like drones, the method of designing a robotic stays the identical.

Fundamental Robotic Design

Earlier than you begin designing your robotic, that you must perceive what downside it can clear up. What sort of robotic is critical? Will it’s stationary or cell? Will it work together immediately with people and different robots? Does it must “see” issues or have important arm movement? These are a couple of high-level questions that must be thought-about at the start of the design course of.

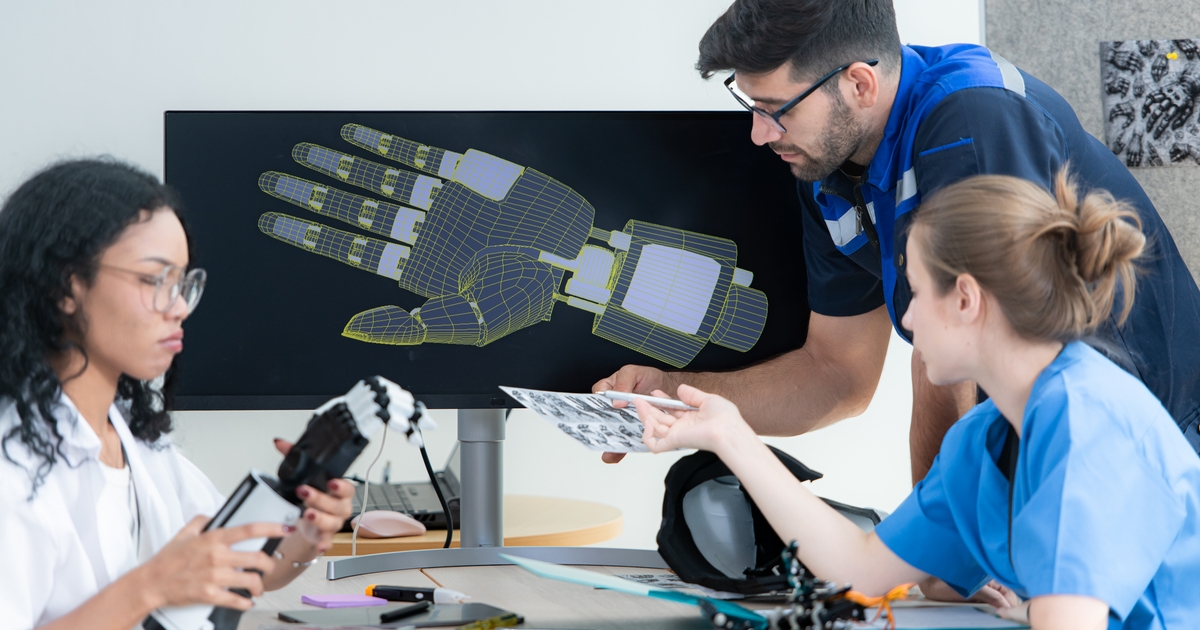

Designing a contemporary robotic requires at the very least a working information of electromechanical (or mechatronic) methods, i.e., the collaborative, built-in growth of digital/electrical and mechanical elements to carry out the wanted features whereas assembly the general necessities. Prototyping and simulation through CAD instruments are sometimes required for an optimum design.

An enormous development in electromechanical methods is miniaturizing all electrical/electrical and mechanical elements. The shrinking measurement of chips has enabled the miniaturization of boards and different methods, which is why smartphones, wearables, and even automotive autos have grow to be smaller and extra compact. Mechanical miniaturization has resulted in small actuators, gears, and motors—some so small they will simply match contained in the human physique. The advantages of miniaturization are being loved throughout many alternative fields of utility, from sensors, wearables, and medical gadgets to satellites, drones, and even video video games.

A mini drone. ajcespedes/iStock/Getty Photos Plus through Getty Photos

Let’s contemplate the varied electromechanical engineering disciplines that have an effect on robotic design.

Mechanical Design

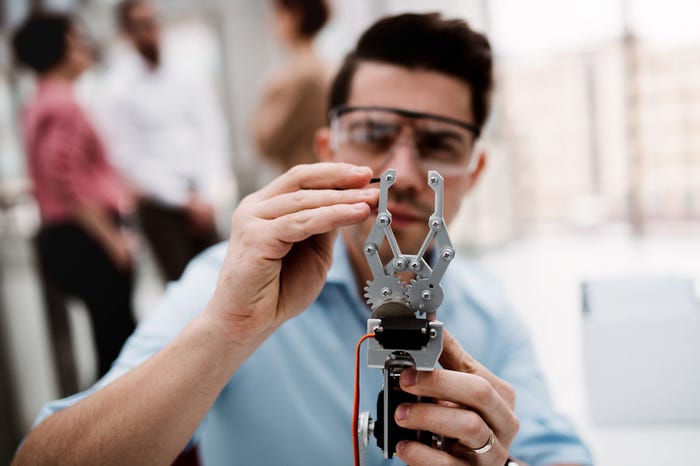

Most of as we speak’s robots require movement; thus, mechanical design abilities particularly centered on motors (largely DC), gears, and actuators are important. A {hardware} prototype is commonly wanted to make sure all elements work collectively as deliberate.

One of many largest challenges for cell robots is balancing, particularly if they’re to hold a load. Gyros can be utilized to find out orientation, that’s, to measure a rotation from a balanced place that may decide changes to keep up uprightness. Robotic steadiness could be achieved with old-school analog, mechanically spinning tops or with newer applied sciences to find out the angular price, akin to ring laser gyros or tiny microelectromechanical system (MEMS)-based gyros that use vibrating buildings of small, resonating, mass sensors to detect shifts in angular velocity.

A strong design for robotic linear movement would come with an array of complementary inertial sensors to measure movement in as some ways as potential, e.g., accelerometers, gyros, and even magnetometers. Inertial measurement models (IMUs) sometimes present six levels of freedom, that means that they include three accelerometers—one for every of the three bodily coordinates (x, y, and z)—plus three gyroscopes for every axis. In IMUs, the variety of levels of freedom is the variety of accessible impartial readings. A few of the newest IMUs have 9 levels of freedom, including three magnetometers to the present inertial-sensor combine.

Digital Design

Until you are nostalgic for steampunk robots that use primarily mechanical methods, you will need to embody electronics in your designs. For instance, whereas mechanical actuators are the muscular tissues of a robotic, the preferred actuators consist of electrical motors that rotate a wheel or gear. Thus, an understanding of electronics and microcontroller-based motors, elements, and energy is required to design mechanical subsystems.

To regulate the mechanical efficiency of a robotic, electronics are wanted to course of knowledge from many sensor inputs and resolve what motion to take. Particularly, sensors give details about the setting or the robotic itself, e.g., the place of its arms, legs, finish effectors, and the like. After processing this data, the robotic sends (both wired or wirelessly) the calculated indicators to the actuators (motors), which transfer the mechanical construction to realize the required coordinated movement.

Robots want electronics to know and act on knowledge collected by sensors and to help a CPU. PhonlamaiPhoto/iStock/Getty Photos Plus through Getty Photos

Electronics additionally act as a robotic’s CPU-based mind, processing sensor knowledge, making choices, executing directions, and coordinating the interplay of assorted elements of the robotic’s {hardware} and software program methods. This important element has revolutionized the sphere of robotics, enabling machines to carry out duties autonomously and with rising complexity.

In fact, the CPU depends on software program applications to offer directions and algorithms for the robotic’s operation. These applications are sometimes developed by robotics engineers and programmers who work intently with the {hardware} designers to make sure integration between the CPU and the robotic’s different elements.

Programming

A CPU for a mind does little good with out code to go together with it. As soon as the electronics are in place, the microprocessor or microcontroller system have to be programmed to know methods to act and interface with the encompassing world. Whereas microcontrollers are usually used for extra repetitive duties, microprocessors allow superior duties akin to picture processing, synthetic intelligence, mapping, and path planning. The highest robotic programming languages are C/C++ and Python and are used to do every thing from the motor operate of a robotic arm to AI performance.

Python is comparatively simple to make use of because it incorporates a choice of libraries to implement the important robotic operate. Utilizing coded libraries usually means fewer strains of code are required, making Python quicker and simpler to make use of than conventional C/C++. Python reduces programming time by eliminating the necessity to outline and forged variable varieties and permitting motions to be coded in the identical script. Python’s recognition means it has a big neighborhood of builders to offer assist and steerage. To study extra, see “Fundamentals of the Python Programming Surroundings.”

For a easy robotic, you may want a primary understanding of coding, however you do not have to be a professional. Typically, you may copy and paste code from the Web so long as the code is appropriate with the robotic {hardware} and firmware. However watch out that the copied code is from a dependable supply and freed from viruses or harmful buildings.

Prototype or Manufacturing

One further consideration in designing an electromechanical marvel is whether or not it is a prototype—typically referred to as a proof-of-concept (one-of-a-kind)—or one thing that will likely be mass-produced. These aren’t mutually unique decisions, as a prototype may nicely result in a manufacturing run, nevertheless it helps to know the distinction since it can have an effect on your selection of supplies and design alternate options.

The choice to make one distinctive or many industrial robots can even have an effect on the machine’s look, really feel, and fabrication. The enclosure of the robotic is set by the robotic’s performance and the aim it serves. Whereas enclosures are wanted to guard inside elements like actuators, gears, and electronics from environmental issues, engineers may also use enclosures to provide the robotic persona and create an acceptable interface between people and different robots.

Robotic designers ought to have an understanding of electromechanical (or mechatronic) methods, electronics, and programming. Halfpoint/iStock/Getty Photos Plus through Getty Photos

Robotic Engineering Lifecycle Course of

When you perceive the completely different engineering applied sciences concerned in making an entire robotic, it is essential to know the event course of. Since making a robotic requires a wide range of engineering disciplines—electronics, mechanical, and laptop science, to call a couple of—it already intently follows the fundamental lifecycle course of, as outlined beneath.

1. Outline the Downside

First, you will need to decide the aim and design of the robotic and write down the necessities, from a excessive stage to specifics. For instance, a robotic may want to maneuver amongst people, which ends up in interface and security necessities. The robotic should transfer at a secure velocity when transferring round people. Thus, it should pay attention to people and reply to their altering positions. All the necessities must be documented for the design actions and to later show they have been met through a verification and validation course of.

2. Answer Architectures

After getting an affordable set of high-level necessities, you may start to put out the robotic’s performance, resulting in the task of preliminary {hardware} and answer architectures. For instance, for a robotic to maneuver, it can want particular mechanical elements managed by software program. How will the robotic’s subsystems, i.e., the completely different legs and arms, be directed at a system stage? How a lot energy will all of the methods require, and at what price?

Because the robotic’s total performance is healthier understood, extra particulars will should be thought-about, akin to figuring out the necessities of particular actuators, motors, sensors, and batteries/energy provides for the design. Primarily based on the detailed features the robotic should carry out, it’s possible you’ll must design subsystem imaginative and prescient sensors and proximity-detecting sensors, maybe primarily based on ultrasonic, infrared, and even fiber optic cable-based sensors.

3. Design Options and Tradeoffs

Along with technical necessities and performance, contemplate price and time points. Typically, constructing a prototype will assist reply questions on which features must be applied in {hardware} versus software program to fulfill necessities, performance, and time schedules and stay inside finances.

To find out the optimum steadiness amongst competing design alternate options, it is essential to recollect elements such because the setting, energy, sensor choice, and total fabrication points, amongst different concerns.

Until the robotic is stationary, the setting wherein it should function will likely be a big consideration. What terrain will it must navigate, from a hospital hall or commerce present ground to a producing or warehouse facility to roaming round a distant moon or planet? What environmental circumstances should it face up to, akin to mud, humidity, vibration, and water intrusion? The setting will dictate the forms of sensors (e.g., acoustic versus laser-based) required and their ruggedness.

Different robotic necessities, akin to movement, can even decide sensor choice. Typically, a proximity subsystem will likely be part of any design to detect objects with which the robotic should keep away from or work together—as with people or a management panel. Many forms of proximity sensors are primarily based on many alternative applied sciences, akin to embedded imaginative and prescient cameras, ultrasonic gadgets, laser-based lidar, and others. The choice of sensors should even be balanced with all of the completely different sorts of knowledge the robotic wants to amass from the bodily setting and the way it is going to be processed – which is expounded to the processing energy of the CPU electronics.

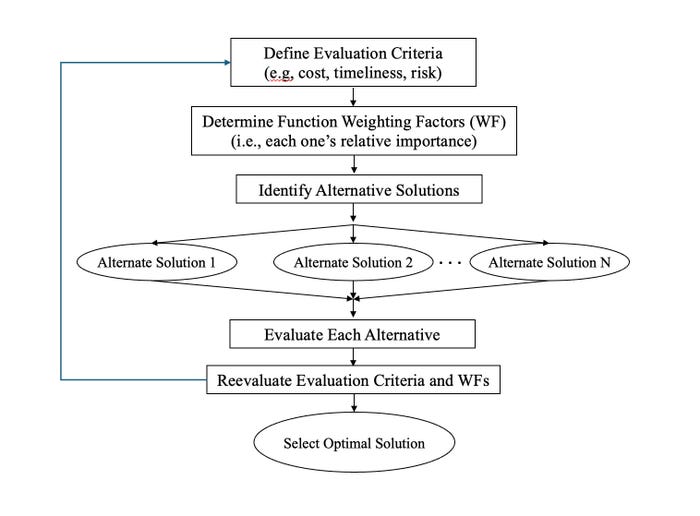

The ensuing environmental and sensor necessities have to be balanced in opposition to the ability and price necessities of the general robotic. Choosing probably the most acceptable answer from a number of competing alternate options isn’t a simple process. Engineers sometimes use commerce research, or tradeoff evaluation, to logically consider different options’ relative deserves. A commerce research is a proper course of wherein two or extra competing different options are in contrast relating to technical attributes, threat, price, schedule, and different issues.

Typical technical commerce research course of. JOHN BLYLER/JB SYSTEMS TECH

Energy is one other main constraint on the design of a robotic. Will it require batteries to function, or should it’s tethered to a wall for energy? Each system element wants energy, so an total energy requirement have to be decided. Time can also be a consideration right here since some elements will want extra energy at completely different occasions, e.g., if a robotic arm is lifting a heavy object.

Energy consumption is a vital element of any electromechanical system that have to be thought-about on the very begin of the design. The choice of all digital and electrical elements should all the time contemplate the system’s total energy necessities. If too little energy is accessible, then components will not work. If an excessive amount of, the ability methods are overdesigned, thus losing price and effectivity.

One other frequent tradeoff consideration is the load and form of the system. How a lot will the robotic weigh, and is there a weight restriction? Is there a restrict to the robotic’s measurement (particularly peak)? If it is too tall, will it’s unstable because it turns a nook throughout movement? One potential answer is to make use of miniaturized elements to cut back the load and form of the system, however how will the price and total performance be affected? A number of commerce research will reply this query, however finest practices recommend that flexibility is vital in design. One uncommon instance of flexibility is the design of a robotic cat-like tail for astronauts to assist keep their steadiness in weightless area. (See Learn how to Construct Your Robotic Tail.)

Constructing {hardware} prototypes and coding fast software program prototypes will assist reply tradeoff evaluation questions and decide the easiest way to fulfill necessities and time schedules and stay inside finances.

4. Implement the Answer in {Hardware} and Software program

The fourth step to creating a robotic is to construct and program your {hardware} subsystems and wanted knowledge processing. All components, such because the body, the sensors, the motors, cables, and the batteries or wall outlet plug, have to be assembled. You’ll need to add the required code that may management the conduct and logic of your robotic, such because the motion, collision avoidance, performing particular duties (like lifting an object), and relaying data to others. Many programming platforms can be found, akin to Arduino, Raspberry Pi, or LEGO Mindstorms, in addition to extra CAD-based skilled instruments.

5. Check, Verification, and Validation

Testing, verification, and validation strategies and processes are used to make sure that you have really met the entire necessities within the robotic system design. What’s the distinction between these three phrases?

Once you check, you make sure the product or system works, however solely after you may have constructed or acquired the product elements, chips, boards, packages, and subsystems.

Once you confirm, you make sure the product or system works earlier than it has been created or manufactured. In methods engineering, you will need to be certain that your design meets the necessities. On this approach, verification is a type of testing, however verification tends to be trickier as you check one thing earlier than the product exists, whether or not in software program or {hardware}.

Lastly, validation checks whether or not the specification captures the shopper’s intentions, whereas verification checks that the system or elements meet specs.

Because the robotic is being constructed and assembled, it’s a necessity to verify it really works as meant and meets the necessities and constraints you outlined in step one. It’s worthwhile to use completely different strategies, akin to commentary, measurement, and simulation, to gather knowledge and analyze the efficiency and effectiveness of your robotic system. Any {hardware} failures or coding errors, bugs, and points have to be documented and resolved.

Even the prototypes should be examined, e.g., the early breadboards upon which the preliminary programming was begun. All sensors, motors, actuators, imaginative and prescient subsystems, and the like must be examined utilizing the breadboard operating the mandatory code and drivers.

As soon as the subsystems have been examined and verified, every thing must be mounted and secured upon the robotic’s structural body and chassis. Loads of third-party distributors present robotic chassis, however it’s possible you’ll must construct one your self—relying on the robotic’s required performance.

6. System Check and Operation

By now, it is best to have a completed robotic, however some last changes to the {hardware} and updates to the software program should be wanted. Additional, if necessities for the ultimate system have modified considerably, it’s possible you’ll want to think about main redesigns, however hopefully, that will not be the case. Nonetheless, though your robotic is now full and finalized, be open to creating any changes for steady enchancment. Chances are you’ll discover that you just want additional sensors or that the ability consumption is simply too excessive.

Occasions Have Modified—Constructing a Robotic Immediately

Whereas the fundamental growth course of stays the identical, the design device suites for robotics have modified within the final 20 years. Up to now, designing a robotic was a really complicated course of requiring engineers to cope with the interdependencies between the system’s bodily construction, sensory and motor layouts, and conduct. As mentioned within the earlier part, each growth element was achieved manually, requiring months or years of iterative designing, prototyping, and testing. Simulation has undoubtedly helped, however requires a number of computing horsepower and particular abilities.

Although nascent expertise, AI methods are poised to considerably support people in designing their megatronic counterparts. For instance, moderately than assume a selected anatomical type for a proposed robotic, AI-based design aids contemplate the practical necessities to find doubtlessly new methods to implement mechanical movement. This strategy guarantees quicker design, manufacturing, deployment processes, and distinctive robotic designs.

On the software program growth aspect, generative AI permits low- and even no-code creation. Instruments like ChatGPT can generate moderately practical code on demand. This expertise can also be utilized in embedded imaginative and prescient and sensor-based markets, e.g., to enhance robotic vacuum cleaners and self-navigation drones. This is a clip of a staff led by Northwestern College researchers that has developed the primary synthetic intelligence (AI) up to now that may intelligently design robots from scratch.

Abilities Wanted for Robotics

As you will have guessed, the event of robots can require numerous abilities, together with information of electronics, mechanical design, and software program programming. If engaged on a staff venture, the perfect developer will likely be a system-of-systems engineer who can talk successfully with many alternative engineering disciplines and venture administration.

Nonetheless, having specialised information and experience will likely be an enormous plus, in areas akin to software program engineering, imaginative and prescient engineering, AI engineering, and electromechanical (mechatronic) engineering.

Whereas the design of a robotic system could be complicated and time-consuming, the outcomes are altering the world round us, and often for the higher.